Nanoracks made it first demonstration of metal cutting in space. TechCrunch he says:

The experiment was carried out in May by Nanoracks and its parent company Voyager Space, when it was in orbit with the launch of SpaceX Transporter 5.

However, the company recently published (on Friday) the details of the project. The goal of the Outpost Mars Demo-1 mission was to cut a piece of corrosion-resistant metal similar to the outer casing of its Vulcan Centaur United Launch Alliance something common in space debris.

Cutting was done using a technique called grinding friction. Welding and metal cutting is an operation on Earth that produces dust and debris, which simply falls to the ground.

But when it becomes "at space, in a vacuum, that doesn't happen,” Marshall Smith, senior vice president of space systems at Nanoracks, told TechCrunch in May. "What we want to do is limit the debris, not necessarily because it might be a matter of micrometeorites, but mainly because we want to keep our work environment clean."

The whole project took about a minute. The main objective – cutting a small sample of steel – was successfully completed. It was conducted in collaboration with Maxar Technologies, which developed the robotic arm that performed the cutting. This arm used a commercially available friction milling effector and the entire structure was installed on the Outpost spacecraft to ensure no debris would escape.

Indeed, one of the main aims of the demonstration was to produce no garbage – and it worked.

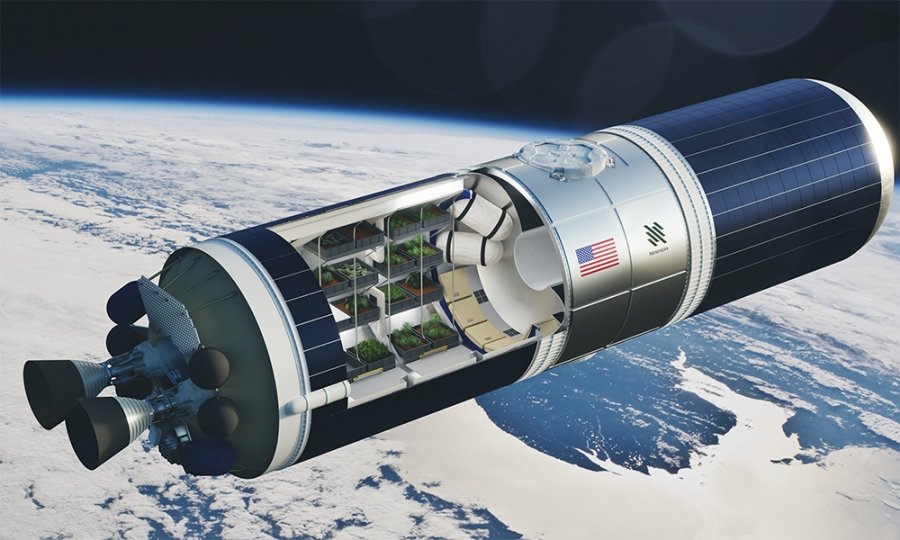

Nanoracks cut a type of very durable metal that usesin the upper stage of a rocket because the company's long-term goal is to modify these used upper stages and turn them into orbital platforms.

According to Smith, this is just the beginning. In the future, Nanoracks will attempt larger-scale cuts in its quest to eventually realize larger structures.